Cementing consultancy

- Technical Expertise: Access specialised professionals in cementing technologies and ensure optimal well integrity.

- Customized Solutions: Tailor strategies to your project’s unique parameters. Maximise performance and lifetime zonal isolation.

- Risk Mitigation: Proactively identify and mitigate hazards related to well safety and environmental impact.

- Regulatory Compliance: Stay compliant with evolving regulations and industry standards, ensuring efficient and responsible operations.

- Performance Optimization: Enhance productivity and longevity through meticulous optimisation of methodologies and quality assurance.

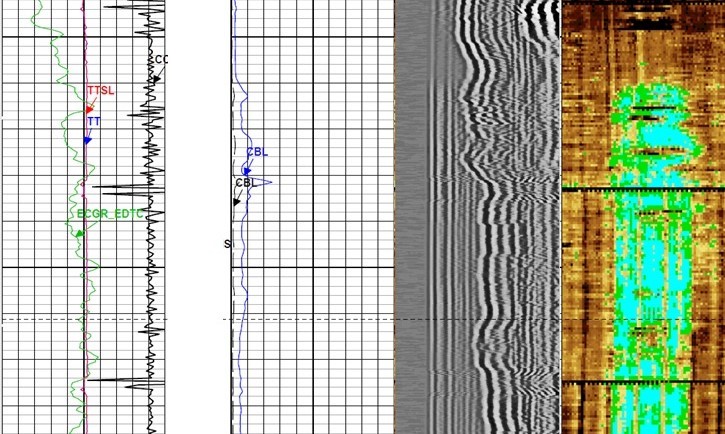

Interpretation of cement evaluation logs

- Ensure Well Integrity: Cement evaluation logs provide critical insights into the quality and effectiveness of the cement job, helping verify zonal isolation, therefore, ensuring well integrity.

- Optimise Production: Accurate interpretation of cement evaluation logs allows for precise identification of any cementing deficiencies. By addressing these issues, operators can optimise production by minimising water or gas influx, enhancing reservoir connectivity, and improving overall well performance. Also, this contributes to the continuous improvement of future cementing jobs.

- Risk Mitigation: Interpretation of cement evaluation logs enables early detection of potential cementing failures or defects, mitigating risks associated with casing collapse, sustained casing pressure, or formation damage. Addressing these issues promptly reduces the likelihood of costly remediation work or environmental incidents.

- Compliance and Reporting: Cement evaluation logs play a crucial role in regulatory compliance and reporting requirements. Accurate interpretation ensures that well construction meets industry standards and regulatory guidelines, facilitating smooth approval processes and minimising regulatory risks.

- Cost Efficiency: Efficient interpretation of cement evaluation logs can lead to cost savings by identifying issues early in the well’s lifecycle. By detecting and addressing cementing failures promptly, operators can avoid costly remediation work, minimise non-productive time, and optimise operational efficiency over the well’s lifespan.

Long-term zonal isolation engineering

Enhanced Well Performance: Zonal isolation engineering optimizes reservoir connectivity, minimizing fluid interference and maximizing production potential. This translates to increased profitability for clients through higher production rates and improved well performance.

Cost Savings and Efficiency: Investing in zonal isolation engineering reduces the need for costly interventions and remediation work down the line. Clients benefit from lower operational costs and enhanced efficiency, leading to improved returns on investment over the well’s lifecycle.

Training

Investing in specialised training for cementing operations and interpretation of cement evaluation logs is vital for optimising well construction. Equipping personnel with the necessary knowledge and skills not only enhances operational efficiency but also reduces risks associated with inadequate zonal isolation and casing integrity. Well-trained teams can proactively identify and mitigate potential challenges, minimising downtime and costly remediation efforts, ultimately fostering long-term success and stakeholder trust.

Tender preparation and evaluation

With the input of a cementing expert, tenders are meticulously prepared with accurate technical specifications and requirements, eliminating ambiguity and reducing the likelihood of misunderstandings or disputes during the bidding process and the contract’s execution.

Quality assurance and auditing

- Enhanced Confidence Through Verification: Confidence in cementing operations can be elevated with third-party quality assurance and audits. Independent verification ensures adherence to industry standards and regulatory requirements, bolstering trust in the integrity and reliability of the well construction activities.

- Driving Excellence: Through detailed assessments and feedback from third-party audits, continuous improvement in cementing practices can be facilitated. This ensures a commitment to excellence in well construction, ultimately driving long-term success and operational efficiency.

Decommissioning: plug and abandonment

- Specialised interpretation of cement evaluation logs, customised for plug and abandonment processes, guarantees detailed well closure planning, effectively mitigating the potential for expensive delays or environmental complications during decommissioning projects. Accurately assessing well integrity and cement barrier effectiveness facilitates seamless regulatory compliance efforts, ultimately enabling streamlined, eco-conscious well closures

Internal cementing standards and guidelines

- Establishing internal cementing standards and guidelines ensures consistent quality, operational efficiency, and regulatory compliance during well construction. Internal standards provide clear guidance to personnel, reducing the likelihood of errors and improving the reliability of cementing operations. In addition, this fosters operational excellence and strengthens the company’s reputation as a reliable and environmentally responsible leader in the industry.